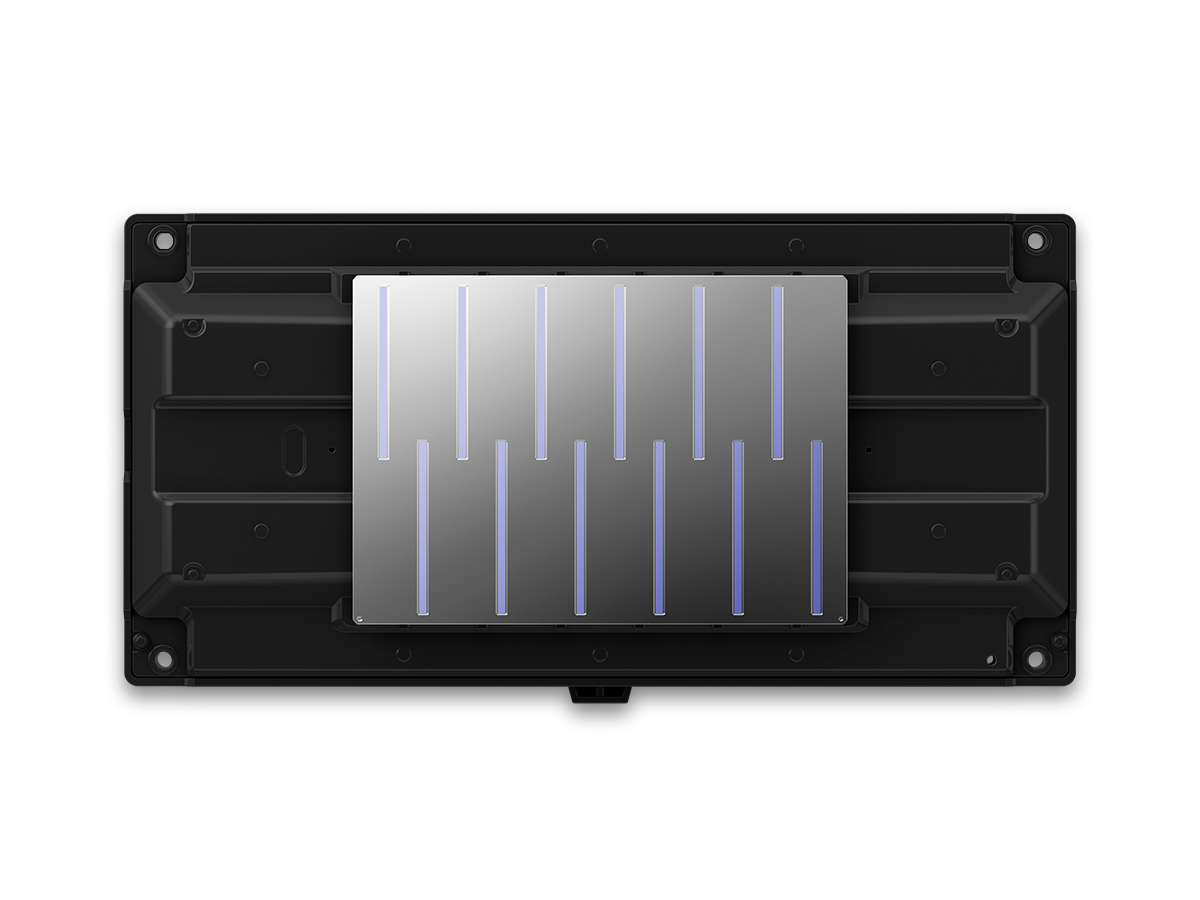

Integrated Ink Pack System

The new ink packs on the Integrated Ink Pack System is now 45% larger1, which helps to reduce printer downtime and replacement frequency while reducing packaging waste. The 1.6L ink packs only need to be shaken and inserted, which means there's no need for pour and stir, which can create a mess.

Reliable and Improved Productivity

Equipped with the all-new 2.64-inch PrecisionCore MicroTFP printhead, printing speeds are improved by approximately 30%2.

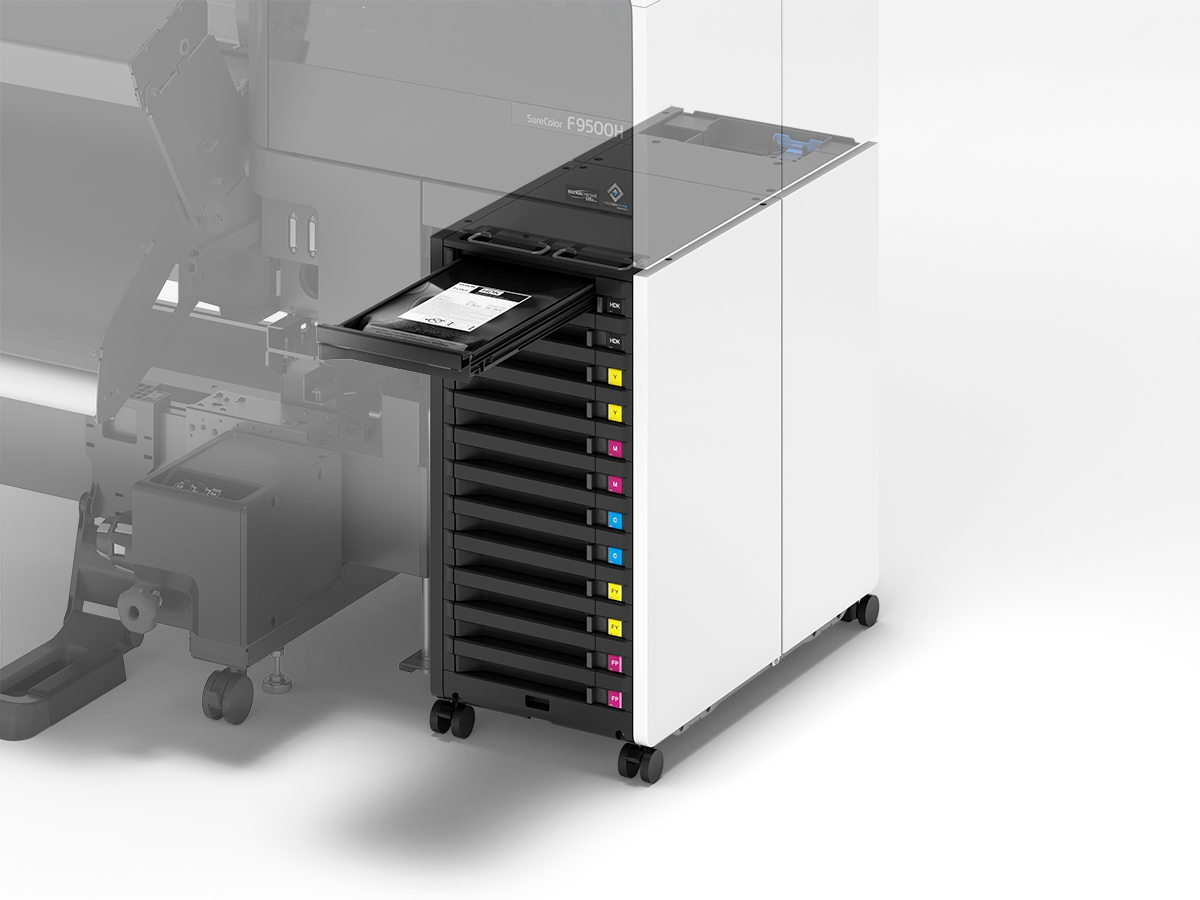

Bulk Ink Supply system, ensures continous printing by automatically switching to the backup ink supply unit when one runs out of ink. This minimizes printer downtime, allowing for continuous production without any printing interruptions.

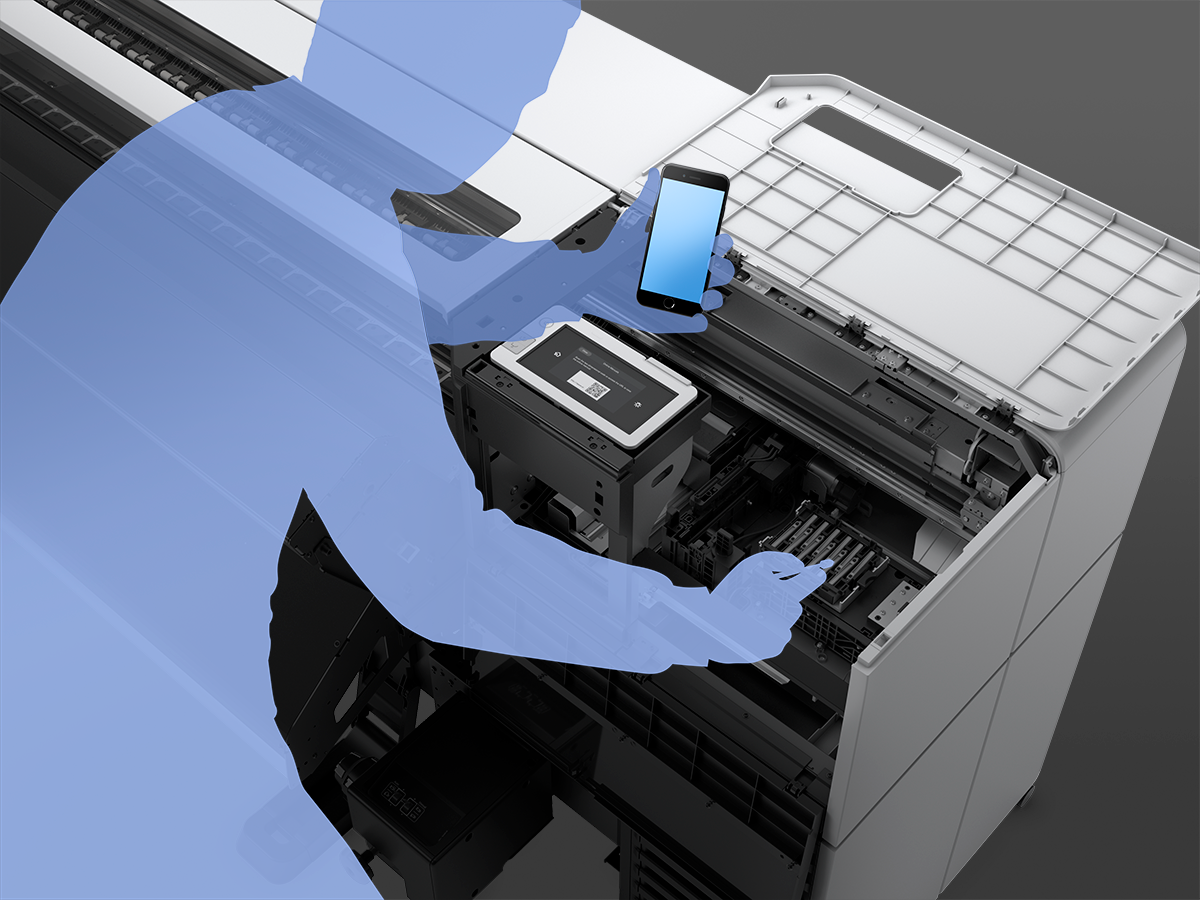

Improved usability

The LCD panel has been upgraded to a 4.3” touchscreen LCD panel, displaying printer information as well as receiving user inputs. Allowing for a user-friendly experience.

The maintenance area has also been enlarged by 183%3, allowing for a easier and faster printer maintenance, reducing printer downtime.

Top surface of the printer is flat, this allows work/discussion to take place on the top of the machine without moving around

SC-F9530 comes with a Media Lifter which allow one-man operation. Individual can load and replace heavy media effortlessly by using the media lifter. Media Lifter is magnetized and can be store easily underneath of the printer without taking additional space.